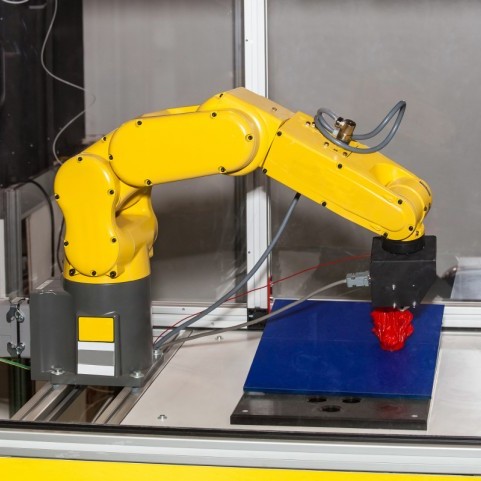

SPENO International SA specialises in rail maintenance worldwide. Its activities include a full range of services from research and development through to the construction and operation of specialized trains and machines to support its activities. SPENO global operations maintain rails on lines used for all types of railways, including underground, tramways, heavy-haul and high-speed trains. Its trains are always branded in bright yellow.

Millions worth of assets are lost each year as a result of a fire related incident involving some form of transportation. Human error, flammable fluids, electric short circuit or excessive heat are mutual causalities. Consequently, fire incidents involving trains impact adversely on train operators and have multiple collateral effects regarding, insurance premiums, health and safety concerns, crisis management and business continuity. These risks must be mediated by fire engineering specialists.

Design, commission, install and maintain a state-of-the-art fire detection and suppression system to protect the SPENO railway maintenance trains. Mechanical equipment employed on trains are challenging to protect for both fire engineers and consultants. The chosen technology needs to be effective against multiple classes of fire, require as little maintenance as possible, be environmentally friendly and have a very small footprint since space is marginal in engine compartments. The systems need to be able to activate autonomously as well as manually in order to protect the engine from various fire scenarios.

FirePro generators are compact and highly efficient. This allows specialists to design highly modular but yet effective fire suppression systems even in challenging spaces such as engine rooms. Complementing this, is the fact that the generators have a 15-year lifetime cycle, no re-filling requirements and very low maintenance. Furthermore, the patented FPC Compound found inside the generators is effective against A, B, C, F, classes of fire and will remain environmentally friendly even after activation. Conventional control panels can be used and/or remain entirely autonomous. Consequently, Fire Engineers employed FirePro technology as a solution to multiple challenges.

FirePro extinguishing generators were placed in the engine rooms along with flameproof fire detectors and CCTV monitoring. A monitor in the Drivers Cabin along with a local control panel and an isolation switch offer an added layer of security and control. The design offers peace of mind to both consultants and the driver of the engine. FirePro Korea delivered an innovative but yet reliable and effective solution to help the end user. Moreover, the eco-friendly FirePro FPC compound remains environmentally friendly even after activation thus strengthening SPENO’s (OHS) Standards.

.png)

.jpg)

.png)

.png)

.png)

.jpg)